PHANTOM

SHIPMENT

PROTOCOL

The Ghost

in the System

Phantom shipments were accumulating in routing clusters across Europe—invalid entries that remained stuck in the system. These non-existent shipments generated unnecessary routes, inflated delivery time estimates, and wasted computational resources. Operations teams spent ~20 hours weekly removing these entries manually, but without proper data collection, identifying root causes was impossible—only addressing symptoms without resolving the underlying issue.

Process Evolution

From manual inefficiency to autonomous cloud execution

Dual-Purpose

Solution

Cloud-scheduled Python solution designed with two objectives: automate phantom removal operations AND systematically collect granular data for root cause analysis—enabling both immediate relief and long-term problem solving.

AUTOMATE

Remove phantom shipments via browser automation

COLLECT

Log every removal: station, timestamp, shipment ID, patterns

VERIFY

Confirm removal success, track exceptions

ARCHIVE

Store comprehensive data for future analysis

REPORT

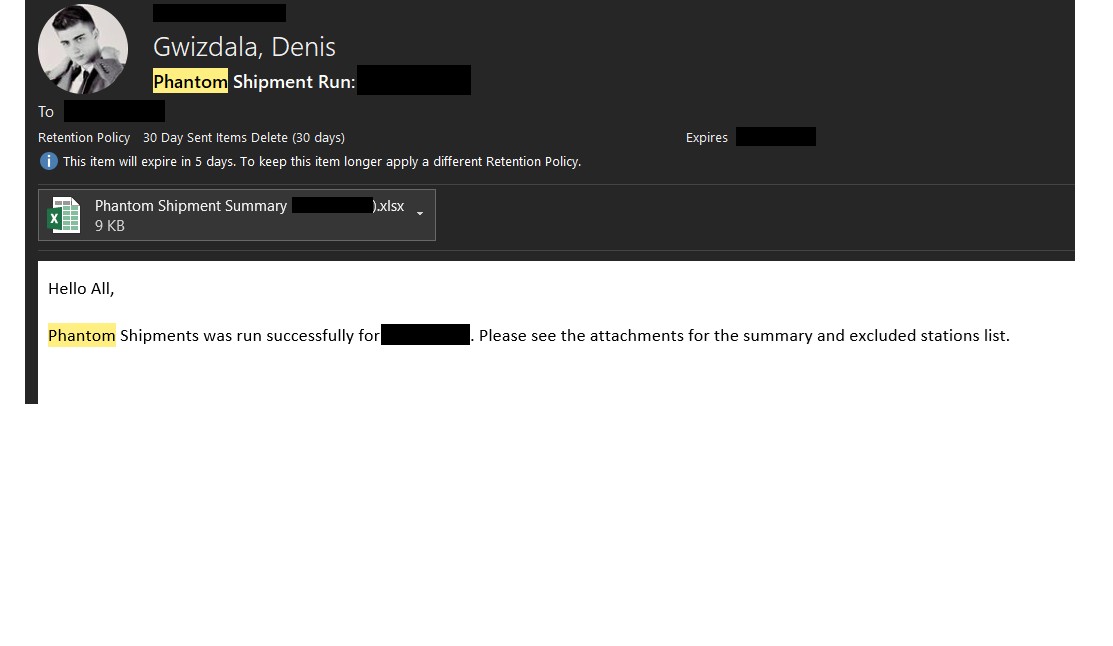

Auto-email stakeholders with removal summaries

Visual Protocol

* Interface shown represents v1.0 with operator interaction. Current production system (v2.0) runs fully autonomous on cloud schedule.

Data Collection Phase

Year-long systematic tracking across EU network—35K+ removals logged with station-level granularity

DAILY ELIMINATION

TOTAL SHIPMENTS REMOVED

Complete Impact

Annually

Cost Avoided

Savings

Impact

Collected

Analysis

Implemented

Eliminated